To modernise and expand operations, the space industry is leveraging cutting-edge technologies like 5G, sophisticated satellite systems, 3D printing, big data, and quantum computing. Space infrastructure is necessary for many services, including long-distance communication, satellite television, weather forecasting, remote sensing, and GPS navigation. Moreover, new developments such as space robotics, smart propulsion, and space traffic management are starting to take off. As the amount of private investment in the sector rises, startups create technologies that facilitate communication, operations, and mobility between Earth and space.

In this article, we would like to share with you 5 ideas from the Novable innovative pool that are contributing to the advancement of the space industry.

Klepsydra Technologies offers solutions that can be applied to Earth observation, aerospace, and space.

Earth Observation refers to the use of technologies in aircraft, drones, satellites, etc. to gather information about the Earth’s environment, surface, and atmosphere. The data is then analysed for the study of conditions such as climate change, weather patterns, natural disasters, and ecosystems.

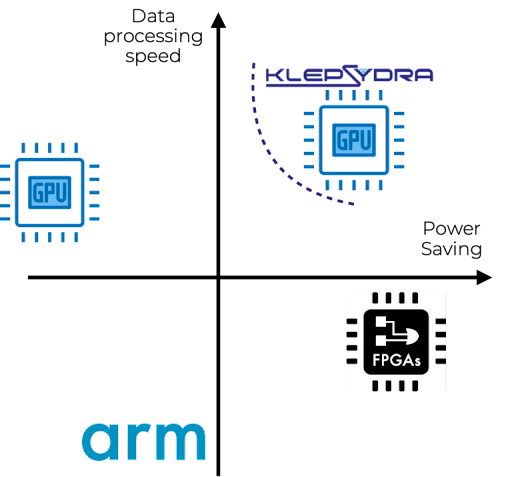

For edge computing applications, Klepsydra has created a sophisticated software framework that offers best-in-class data processing performance while drastically lowering latency and power consumption. This software can be utilised independently or in conjunction with FPGAs (Field Programmable Gate Arrays).

Aerospace macro topics include:

Finally, Klepsydra software for Guidance, Navigation, and Control (GNC) is designed to give high accuracy in applications such as autonomous vehicles, spacecraft, and aircraft.

Mission Control’s software is used by scientists, mission controllers, engineers, and software developers who want faster deployment, valuable data returns, and lower-cost mission development.

Through innovation, Mission Control makes sophisticated software practical for use in space, empowering explorers. Customers can simplify mission development and operations and open up new scientific and commercial opportunities

Streamline mission operations. The company offers solutions to monitor and command remote assets on the Earth, Mars, Moon, and more. It consists of a reliable operations system for your mission, with a flexible and user-friendly interface. Moreover, the cloud server allows you to operate your robot and payload anytime, anywhere.

Enable onboard intelligence. Mission Control provides a way to deploy AI safely across flight platforms to achieve different mission objectives.

Neuraspace was founded to fight space debris with AI. The amount of data about conjunction events has significantly increased in recent years due to the ongoing increase in space traffic and debris. Space operators face an extremely difficult task in this scenario since the conjunction events require a meticulous “manual” analysis that takes time, money, and effort. The automation of this process necessitates the use of AI, and more especially ML algorithms because of their capacity to handle large volumes of data.

Neuraspace allows you to reduce operational manpower efforts, especially for large constellations. There will be fewer false alerts and a shorter delay between the decision to manoeuvre and the close approach. As a result, you will save time and fuel while limiting the risk of collisions and space debris.

The solution feels like an ever-present virtual assistant. Ongoing satellite monitoring, AI-based asset-related alert prioritisation and classification, workflow management, event escalation, and chat for your satellite operators with other companies’ and organisations’ operators.

With this product, you can manage your assets and take on the challenge of debris and an increasing number of satellites in orbit without the need for human experts to determine the criticality of close encounters, as opposed to existing solutions.

Firehawk Aerospace designs and manufactures modern high-performance hybrid rocket engines for the defence industry.

The Firehawk 3D-UltraTM Hybrid Rocket Engine has a highly efficient and streamlined design process that can save costs by 90% and reduce production time to less than a year. Furthermore, the straightforward manufacturing and construction approach is more scalable than anything previously seen in the propulsion sector.

They create incredibly adaptable fuel grains using cutting-edge additive manufacturing techniques. This methodology offers substantial adaptability according to mission specifications, thrust profile, overall impulse dependability, and, above all, economically viable replication.

Scientists can create a cutting-edge hybrid rocket engine with real deep-throttle capabilities for use in commercial and military aircraft thanks to the patent-protected fuel manufacturing process.

Relativity Space aspires to be the next big commercial launcher. The need for space infrastructure is increasing, and as a result, demand for launch services is always exceeding supply. This demand can be satisfied by its 3D printed reusable rockets, which provide clients with the ideal payload capacity at an affordable price. The strategic goal is to decrease the complexity, cost, and time to market of vehicles by utilising the latest developments in additive manufacturing. The patented technologies open up new value propositions in the thriving space economy and allow for inventive designs that were previously unthinkable.

TERRAN R. Government and commercial clients want to launch satellites fast and cheaply, without having to wait for a ride-sharing spot on a big rocket launch to open up. After identifying this gap in the market, Relativity Space created Terran R.

Terran R, designed for reusability, will provide high-volume dependability and performance at a reduced cost and faster time to market. They design and produce reusable, high-performance, affordable rockets by utilising the potential of autonomous robotics, additive manufacturing, and artificial intelligence.

By adopting a vertically integrated technology platform, iteration at a never-before-seen speed and scale becomes possible, pushing the limits of current capabilities and unleashing the full potential of 3D printing in the future. Beginning in 2026, Terran R will be launched from Cape Canaveral Space Force Base’s Launch Complex 16.

Are you passionate about space and new technologies related to the industry? Share your thoughts with us on LinkedIn!